Maintaining battery health during extended inactivity

Long periods of inactivity can drain a vehicle battery, shorten its lifespan, and complicate reactivation. Proper storage routines, targeted maintenance, and sensible use of monitoring tools help preserve battery health and reduce the chance of corrosion or permanent damage. This overview explains practical steps for owners and fleet managers to protect batteries during storage or seasonal downtime.

Battery care during storage

When a vehicle is idle, the battery loses charge from natural self-discharge and from small parasitic draws. Prioritize a full charge before storage and, if possible, maintain the battery with a smart maintainer or trickle charger designed for long-term use. Check battery terminals for corrosion and clean them with a suitable brush and baking soda solution, then apply a thin layer of terminal protectant. For flooded lead-acid batteries, check electrolyte levels and top with distilled water if necessary to keep plates covered.

Storing a battery on a stand or shelf in a cool, dry place reduces self-discharge and prevents ground drains. If removing the battery from the vehicle, label and secure any disconnected cables, and keep the battery away from freezing temperatures to avoid damage. For vehicles kept in garages or storage facilities, schedule monthly voltage checks and charging cycles; maintaining a state of charge above 50% significantly reduces sulfation risk.

Preparing engine, fuel, and lubrication

A well-prepared engine helps the battery by reducing the need for long crank attempts when restarting. Add a fuel stabilizer to the tank to prevent fuel degradation and condensation, and either top off or fill the tank to reduce air space. Change the engine oil and filter before extended storage because used oil can contain acids and moisture that promote internal corrosion if left sitting.

Run the engine briefly after adding stabilizer and fresh oil so fresh lubricant and stabilized fuel circulate. This step also helps distribute oil to seals and moving components. For diesel engines, consider anti-gelling and anti-microbial treatments where appropriate. These engine and fuel maintenance steps reduce later startup stress on the battery and ignition systems.

Role of telematics and diagnostics

Telematics and remote diagnostics can be useful for monitoring battery voltage, temperature, and state of charge while a vehicle is inactive. Fleet telematics platforms often include alerts for low-voltage events or excessive parasitic drains, enabling targeted interventions before a battery becomes irreversibly discharged. Portable OBD-II battery monitors and simple Bluetooth-enabled battery testers provide real-time diagnostics for single vehicles.

Use diagnostics to identify parasitic draws from alarms, onboard computers, or aftermarket accessories before extended storage. Resolving these issues reduces the frequency and depth of recharge cycles required during downtime. When telematics are available, configure notification thresholds conservatively so maintenance staff can act early to preserve battery health and avoid unnecessary replacements.

Protecting tires, brakes, and suspension

Tire pressure and vehicle support affect battery-related decisions because immobilized vehicles may sit in one position for months. Inflate tires to the manufacturer’s recommended pressure or slightly above to reduce flat-spot risk. If practical, move vehicles periodically to change contact points, or support them on jack stands to relieve tires and suspension components.

Brakes can seize or corrode when vehicles are idle, complicating later use and potentially causing longer crank times that strain the battery. Avoid setting parking brakes for long-term storage; instead use wheel chocks or blocks to prevent movement and reduce stress on calipers and parking mechanisms. Regular inspections will catch early corrosion that could influence battery and engine restart efforts.

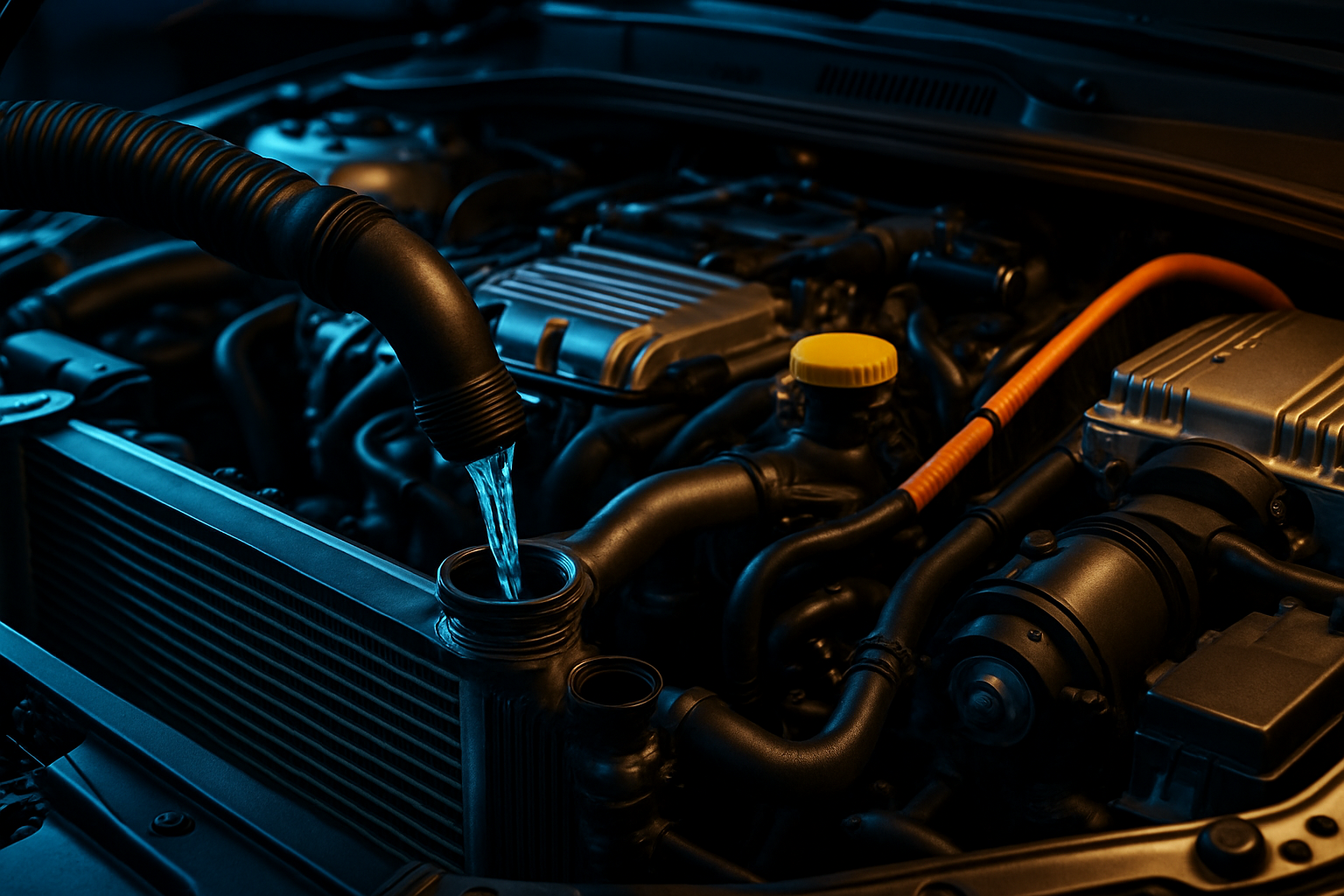

Preventing cooling and emissions issues

Coolant and emissions systems benefit from careful attention during inactivity. Keep coolant levels topped and use the recommended antifreeze concentration to prevent freeze damage and corrosion in the cooling system. Stagnant coolant can corrode passages and affect sensors that influence engine management, potentially increasing demands on the battery during restart.

Emissions components such as catalytic converters and EGR systems can collect deposits when a vehicle is rarely run. Occasional short runs at operating temperature help burn off deposits and keep sensors functioning. Schedule periodic inspections to detect clogged filters or degraded components that would otherwise create harder starts and additional battery load.

Winterization and long-term inspections

When winterization is required, take extra steps to protect battery health. Cold temperatures reduce battery capacity, so store batteries indoors when possible or use insulated covers and heaters designed for batteries. For vehicles that must remain outdoors, maintain a robust charging routine with smart chargers and ensure terminals and cable connections are in good condition to handle cold cranking demands.

Long-term inspections are crucial: check voltage, terminal integrity, fluid levels, and belt condition at least once a month for vehicles in storage. Keep a simple log of maintenance, charging cycles, and diagnostic readings to spot trends such as gradually declining capacity or increased parasitic draw, which indicate when a battery may need replacement.

A final summary Effective battery preservation during extended inactivity combines preventive maintenance, proper storage, and monitoring. Addressing fuel, engine lubrication, cooling, and emissions reduces stress at restart, while telematics and diagnostics help detect drains and voltage drops early. Regular inspections of tires, brakes, suspension, and electrical connections complete a holistic approach that extends battery life and eases reactivation after prolonged downtime.